专业能力

我们的团队融合多学科背景,在产品和体验的设计中采用科学系统的创新方法,以确保市场成功。

以人为本的研究

We thrive on understanding people and identifying the interplay between products, services, systems and cultures.

Our expertise in ethnography and psychology means we can detect unmet and unarticulated needs, desires and aspirations – then translate them into products, services and experiences that engage consumers and business customers.

Our key services include:

Exploratory Research to understand how people live, work and play – our methods include contextual enquiry, naturalistic observation, journal studies, digital ethnography, in-depth interviews and small-group discussions.

Participatory Research to engage people in the design process – we encourage participants to build stories around their experiences and to contribute ideas and concepts.

Concept Testing to get feedback – we work throughout the product cycle to discover how people feel about our early concepts and prototypes through to fully realised products and services.

Related Projects

趋势洞察&设计策略

We uncover the emergent trends influencing the future of your market and translate them into tangible business opportunities. By tracking macro and micro changes affecting your market we identify insights that can be used to drive innovation across product design, service design, business strategy and technical development.

Using a range of design insight tools, we aim to inspire your team and identify commercial opportunities:

Social and cultural – we use the latest insights on people’s changing attitudes, behaviours and lifestyles to create reports, brand maps, persona profiles and future scenarios.

Design and technology trends – we identify the visual design trends likely to influence products and services and track the latest technology developments.

Design semiotics – our semiotic approach to understanding the cultural meaning and expectations attached to products, services and consumer behaviours ensures designs correctly communicate your branding and positioning.

Our design strategy focuses on external factors, such as user experience, local and global trends and competitive/market dynamics, which in combination with internal expertise of creative design, technology application, manufacturing and usability testing, help us create for you a cohesive strategic road map and action plan for project and market success.

Our key services include:

Opportunity framing: translating streams of different research into spaces of potential opportunity, to identify areas that a brand/company can differentiate, innovate and ultimately grow.

Creative translation: we have developed a range of techniques to analyse, filter and fully utilise business aspirations, strategy insights and consumer insights, into meaningful challenges. Helping us validate for you areas of opportunity for innovation and new product/service development.

Creative sessions: crafting creative and collaborative workshops, building traction around ground-breaking insights and designing concepts that will change your market.

Innovation roadmapping: having identified opportunities and translated insights into concepts, we use our experience in product/service development and launch, to map an innovation pipeline that guides future R&D.

Sustainability management: by uncovering the latest eco trends, understanding current consumer behaviours, through to conducting Life Cycle Analysis on products to understand their environmental impact, we can ensure that all CSR needs are included and provide guidance on developing sustainable products and services.

Related Projects

用户体验与交互设计

We apply our expertise in interaction and interface design, as well as prototyping and simulation, to create compelling product and service experiences.

From early concept sketches and storyboards through to fully functioning prototypes, we can help bring ideas to life through:

Product and service check-ups – after evaluating the usability of your products and services, we recommend the improvements that will deliver the best return on your investment and the most benefit to your customers.

Interaction and user interface design – using an iterative process, we design and prototype digital interfaces and physical devices, as well as service scenarios and experiences, then analyse how people interact with each proposed design.

Related Projects

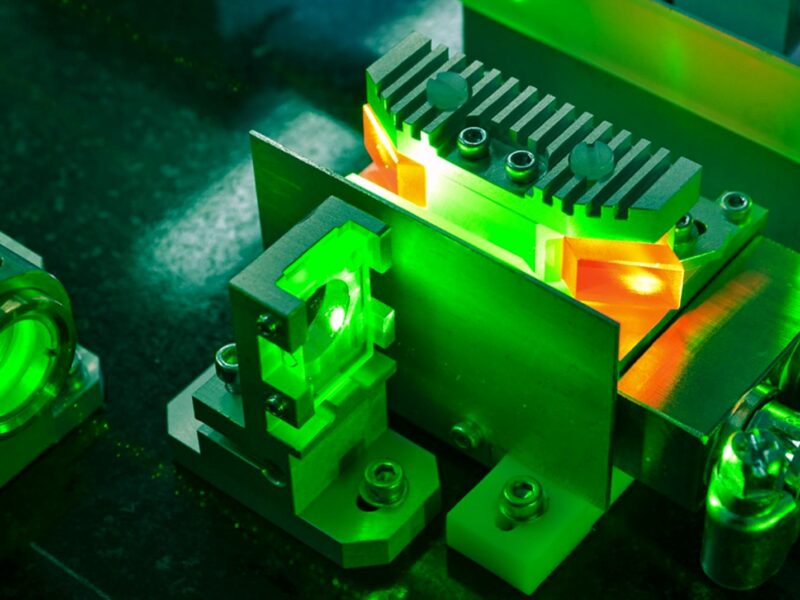

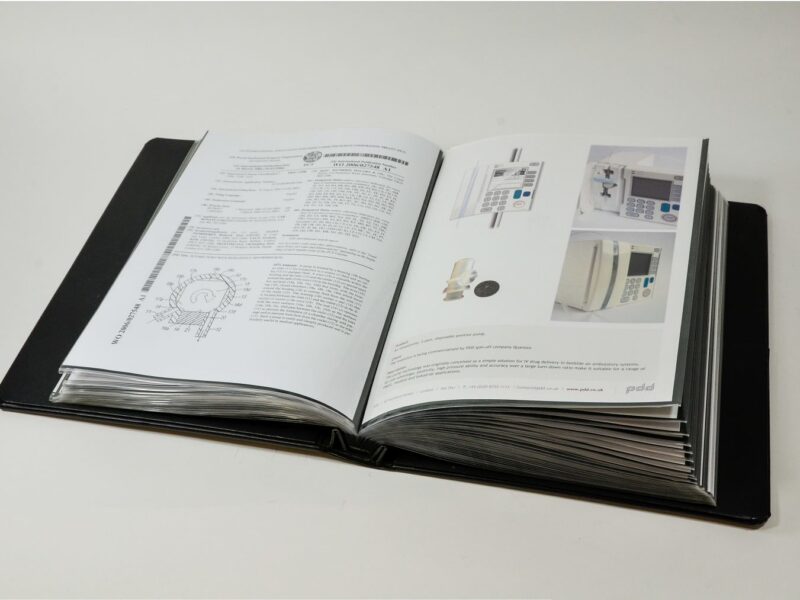

技术与发明

Whether projects are first inspired by new technology or by unmet market need, it’s ultimately the alignment of both that leads to worthwhile innovation and commercial success.

At PDD, we understand the power of inventive technology; it can create new experiences and features, solve long-suffered problems and improve performance, affordability and sustainability.

Through the origination and management of the associated intellectual property, we also help our clients to capitalise their expenditure; turning investment into assets and helping to defend it from undue competition.

Striving to improve and grow involves doing something different and new with the potential for risk, so our teams approach the integration of new technology carefully through:

– Scouting and sourcing appropriate emerging and transferrable technologies.

– Assessing feasibility through theoretical modelling, experimentation and analogous precedent.

– Inventing new solutions, whether by origination, re-application or circumvention.

– Multi-disciplinary integration with Human Factors and Design.

Our keenness for inventive thinking has created many world-first products and the 100s of commercialised patents are testament to the value created for our clients. The most successful companies are consistently those that invest in innovation and PDD is happy to count many amongst its clients

Related Projects

人因及可用性工程

Human Factors

Human factors is not a stage in our process – it is a fundamental foundation that runs throughout the course of every project, from desk-based research through to post-market surveillance.

Usability Engineering

The concept of Usability Engineering (UE) brings together Human Factors, Risk Management and User Experience design to understand and optimise how users interact with medical devices. UE is a regulatory requirement and PDD can fully integrate UE throughout the medical device design and development process or support stand-alone usability testing for your own development projects.

Regulatory Landscape

PDD has a comprehensive understanding of IEC62366 and ISO14971 which are both harmonised under the Medical Device Directive. PDD operates in compliance with the FDA and design guidance documents such as HE75.

Process

In-line with regulatory requirements to develop a UE file for pre-market submissions, we can provide you with a full suite of regulatory documentation to suit the needs of your project.

On-Site Facilities

There are two usability testing rooms at our London studio.

The private rooms can be used for formative or summative evaluations and are equipped with twin ceiling mounted cameras and microphones for recording and remote client viewing.

A wide range of use-scenarios can be simulated such as the home, outdoors or hospital environments. Furthermore, our flexible spaces can facilitate focus groups, training sessions, workshops and interviews.

Our key services include:

For more information on PDD’s usability engineering process click here.

Related Projects

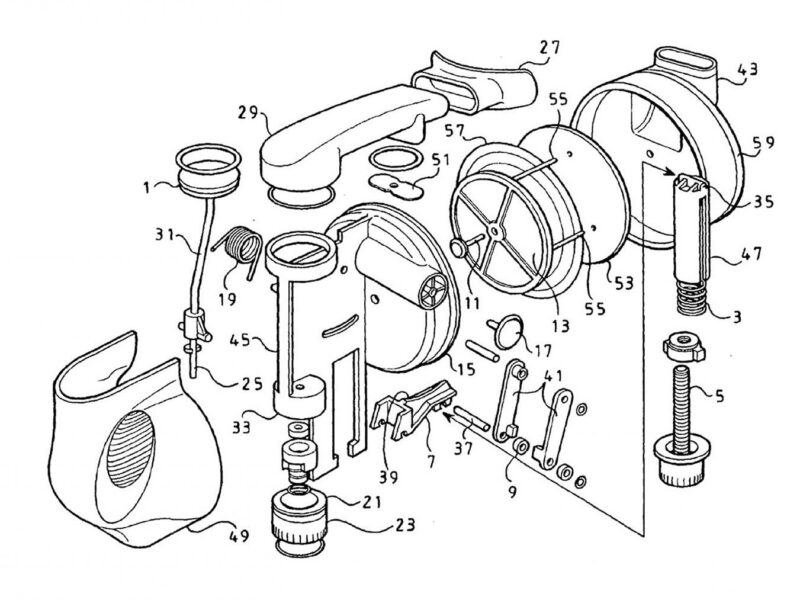

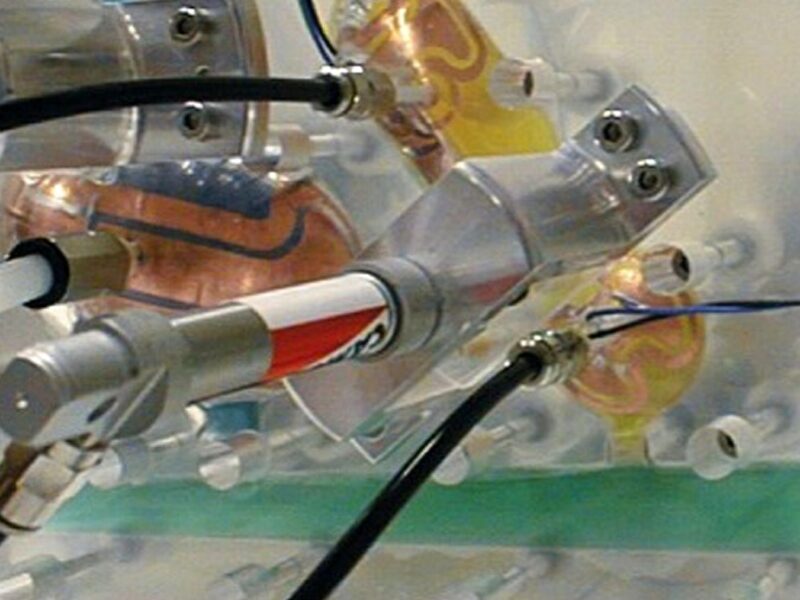

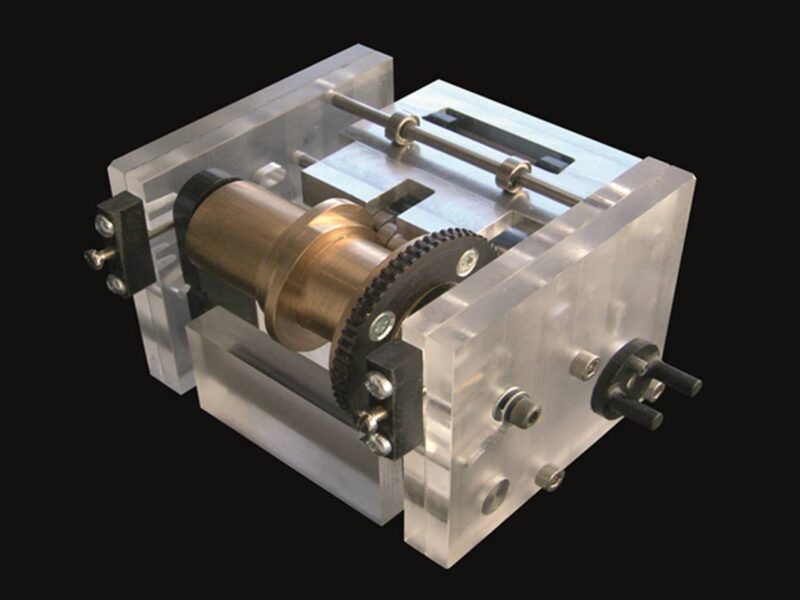

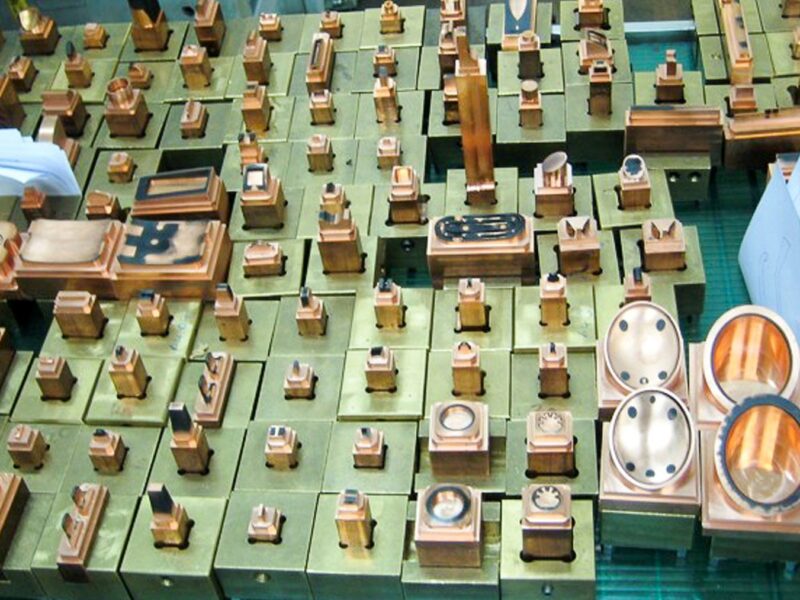

样机制作及验证

Extensive facilities for model, prototypes and test have been fundamental to our ability to turn bright ideas and visionary designs into practical and tangible results quickly and effectively.

We make, test and iterate models and prototypes throughout our development process including relevant ‘looks/works/used and made-like’ characteristics to suit their intended purpose; acquiring insight, mitigating risks and gaining the confidence to proceed.

Early models address form and use, and others explore technical principles, further models establish design appeal and provide technical performance data then full prototypes build design verification and validation ahead of early product samples.

Our experienced model-makers work together with our designers and engineers to convert Computer-Aided Design (CAD) into tangible form using RPT (rapid-prototyping), CNC machining (computer numerical control), manual machining, moulding and casting and hand finishing.

Our visual and robotic metrology equipment is used to inspect parts before assembly and tests in our dedicated laboratory. Equipped with calibrated instruments this is used for experimentation, to characterise prototype performance and to conduct the test verification of medical devices for submission, all managed within our certified quality system.

The models we make at PDD extend from physical products to digital interfaces and often the combination. The quantities range from one to several and also thousands which PDD manages through trusted supply partners. In addition to product, our facility is used to make the associated research stimuli, assembly jigs, test apparatus and limited run tooling.

Related Projects

工业设计及包装设计

We create product and packaging designs that are efficient to manufacture and relevant to your market, while standing out from your competitors.

Our interdisciplinary approach brings ideas to life. We produce beautiful and effective industrial designs and packaging through our expertise in:

Concept Generation & Development – we create seed ideas which we develop into promising concepts, and eventually into more viable, defined solutions.

Design Detailing – we consider and define every element of your product or pack, from functionality and visual sensitivity to tactile response and audio feedback.

Design Communication – we provide you with powerful visualised narratives and scenarios, using hand-drawn sketches, 2D and 3D computer rendering, animation and video.

Colour, Material and Finish – we explore the options, making recommendations and specifications with the help of our in-house CMF library, plus visuals and prototypes.

Visual Brand Language – we translate your brand values into tangible attributes that we can then apply meaningfully to your products and packaging.

Related Projects

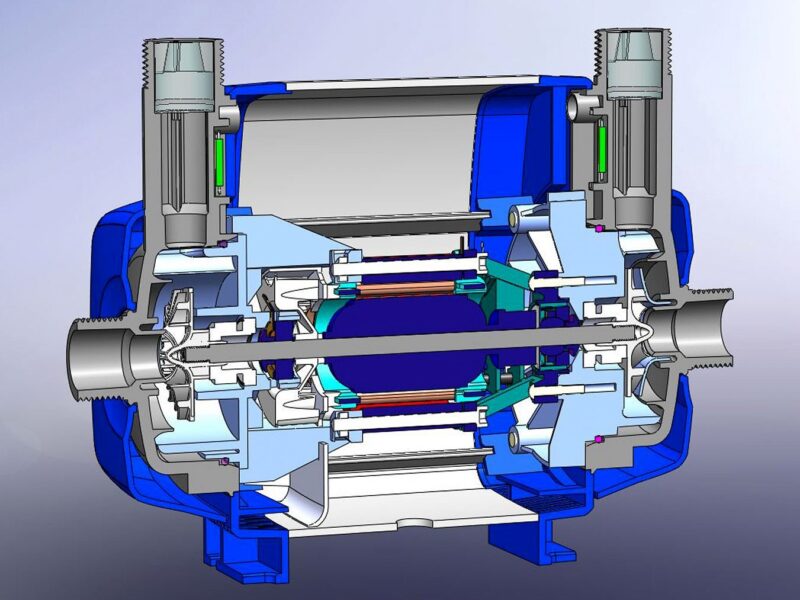

工程设计与仿真

Engineering is a broad term and our teams embrace it from ingenuity through development to detailing, ensuring that bright ideas survive, perform well and will be robust to make without dilution of their appeal or profitability. This work accompanies our other disciplines throughout and covers:

Concepts & feasibility

We steer our talent and experience to create new ideas and synthesise concepts but we ground our optimism with assessment by research, calculation and testing to prove solutions are realistic. We then employ a rational assessment to select the optimum solutions from those explored.

Engineering Development

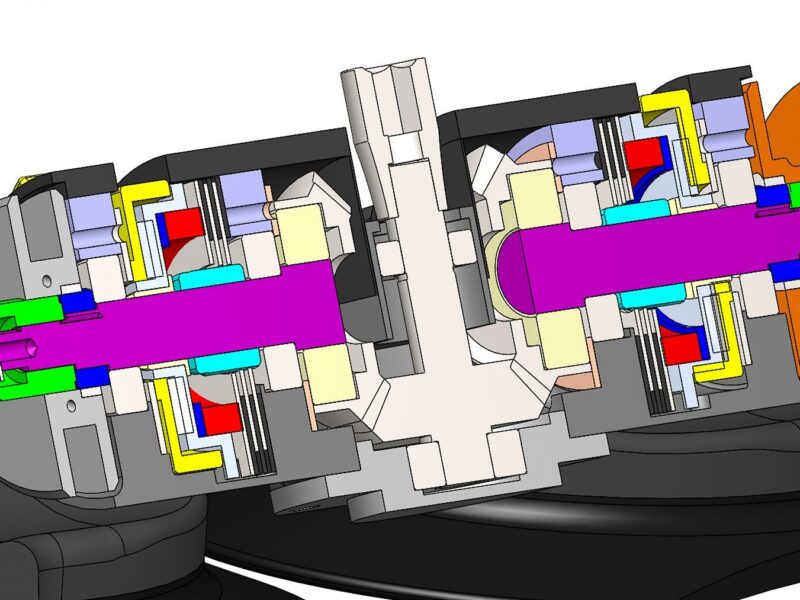

Our knowledge of science, engineering, materials and processes is captured and supported by advanced CAD (Computer-Aided Design) tools and assessed by a risk-driven process to check that regulations, functional specifications, quality targets and manufacturability are achieved and maintained.

Manufacturers are engaged early in the process to ensure designs are suitable for manufacture, assembly, inspection and test.

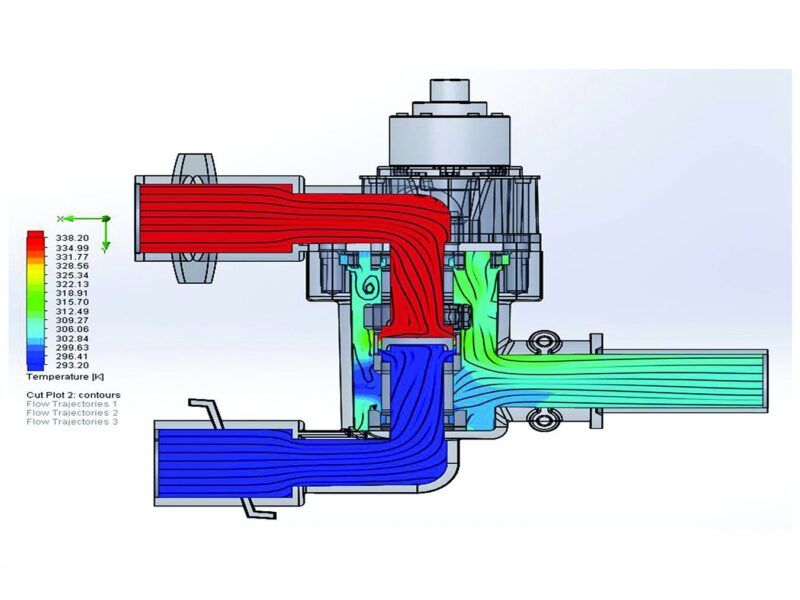

Simulation & Analysis

Our 20-year experience of advanced simulation and analysis tools helps us to explore and de-risk adventurous concepts, optimise designs and help verify that product will still perform at the limits of manufacturing variation. Our capability has evolved with the tools and our MathCAD, ANSYS, Dassault and Creo tools for FEA (Finite Element Analysis) and CFD (Computational Fluid Dynamics) now assess structures, mechanisms, heat transfer and fluids, electromagnetic and impact scenarios.

Specification for Manufacture

Good design needs the correspondingly robust specification to ensure that intent is transferred and requirements are achieved. Our statistical tolerance techniques and assurance of critical functions precedes quality-managed documentation in the form of CAD data, engineering drawings, work instructions and production specifications.

Related Projects

创新培训

Innovating in today’s world is essential to ensure success for your organisation by delivering tangible value to customers and securing sustainable growth. But innovation is not easy. There is considerable risk along the entire continuum – from the outset of uncovering opportunities through to implementing and delivering solutions to people.

Design Thinking – a Human-Centred Design (HCD) approach to innovation is a proven methodology rooted in design and human sciences that helps mitigate the risks associated with the launch of new products, services and strategies. Through better understanding the needs, desires and contexts of the people we’re designing for and with, encouraging collaboration and communication amongst different industry disciplines, and engaging in frequent testing and sense-checking of potential solutions throughout the process we can ensure that we are both designing the right “thing” and designing the “thing” right.

Through our practical, hands-on training programmes, we teach people a flexible framework for practicing Human-Centred Design to accelerate and de-risk the innovation process.

TYPES OF TRAINING

We offer different types of training, from 90-minute Taster Sessions to 2.5+ day, fully-customised workshops. Public workshops are open to any organisation and are scheduled throughout the year. They are ideal if you’re looking for Innovation training for yourself or a few other people from your team and you don’t require customised content.

If you’d like training for larger groups, or customised content and scheduling, then Private (in-house) training is appropriate.

PUBLIC COURSES

Design Thinking for Innovation: Accelerating innovation through Human-Centred Design | Download flyer

A 2-day foundations course teaching participants 20+ HCD methods applied to practice scenarios from different industries.

Design Thinking for UX: User Experience Innovation Through Human-Centred Design | Download flyer

A 2-day course introducing participants to the discipline of User Experience (UX) Design, by exploring Human-Centred Design techniques to create compelling and meaningful user experiences.

Deep Dive into Co-Creation and Participatory Design

This one-day intensive workshop provides a deeper understanding of how to actively involve people in the design of concepts, products and services using methods such as Journaling, What’s-on-your-Radar, Buy a Feature and Build Your Own.

Contact Vassilios Kanellopoulos

Call: +44 20 8735 1111

Email: [email protected]

Upcoming Workshops:

Design Thinking for Innovation: Accelerating innovation through Human-Centred Design | Download Flyer

To register your interest please contact: [email protected]

Related Projects

商务咨询

With considerable project management and practitioner experience, PDD is engaged to provide companies with advice and support outside the scope of innovation projects.

We help companies considering investments, acquisitions, licensing, partnering and subcontract engagement to assess the strengths, weaknesses and opportunities of prospects and plans and advise courses of action to optimise success and mitigate business risks.

Intellectual Property

Our invention and patent circumvention skills, as well as frequent patent drafting and interaction with patent agents, provide the business-focussed inventor and designer perspective on intellectual property to complement the legal position.

Plans, Processes & Teams

Our experience developing, using and training in new innovation processes gives us the position to assess the strength of proposed developments and plans and with our project review capability, we can assess the strength and appropriateness of project teams and solutions.

Innovation Propositions

Our daily management of design innovation gives us the capability to review the strength and risks of proposed designs from the market, commercial, technical and manufacturing viewpoints and advise on gaps, risks and actions.

Quality Management

Having written and improved our bespoke internal quality systems over 2 decades, we are well-equipped to audit the quality management of external parties, alongside an assessment of their capability to deliver in R&D and manufacturing fields.

The format of our engagement varies according to circumstance but can be either independent or accompanied visits and audits or reviews of plans, designs and documentation. The output can combine assessments or due-diligence reports, plans, coaching and external review.

Related Projects

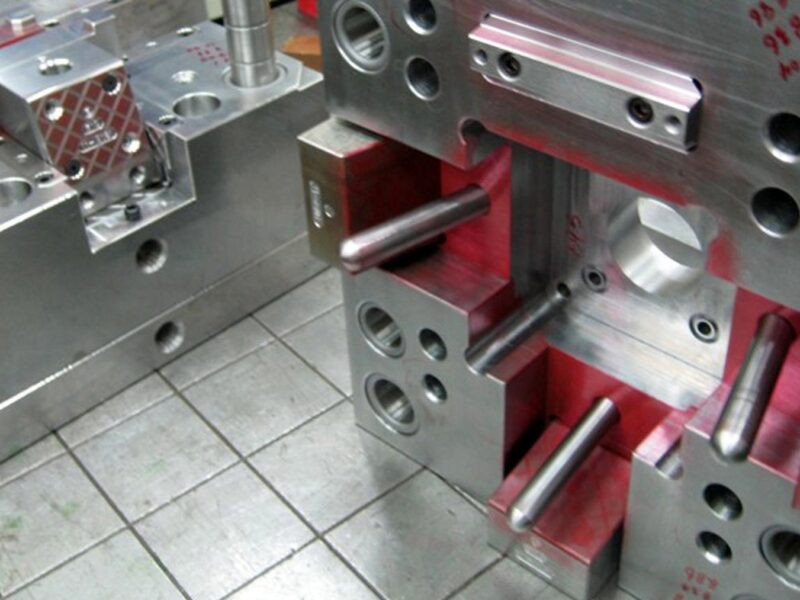

生产与外包管理

From our offices in London, Hong Kong and Shanghai, PDD’s experienced production engineers and managers source tooling and manufacture for many of our clients. Through this, we have built an extensive network of trusted suppliers in the UK, Europe, US, China, Taiwan, Singapore and Malaysia.

Our services are necessarily flexible to client circumstances: we can work with established client suppliers or assess, introduce and manage new suppliers through tooling that clients can engage for manufacture.

Through our subsidiary company ‘Forge Production’ in Hong Kong, we can also tender separately to supply product under a manufacturing contract.

Our quality-assured process for transfer of design data, drawings and documentation starts well within the product development phases; assessing and engaging suppliers, ensuring cost viability and conducting DfM (design for manufacture) appraisal and collaboration in process risk analyses.

We liaise through preproduction, assessing sample inspection, testing and reviewing the supplier qualification of tools, equipment and processes.

We can then help manage logistics and on-going quality assurance monitoring.

With the experience of having implemented the manufacture of many products, PDD also helps clients address production problems on existing products and to improve quality and reduce costs.

Related Projects

电子及软件设计

Our team conceives solutions from an early system perspective and manages the interaction design, development and integration of electronics and software on products, connectivity with the web and the experience on mobile devices.

Our process starts with human-driven system mapping and interaction and functional charting before exploring architecture and technology in breadboard and benchtop models. Our systems engineers and software and electronics specialists work alongside our interaction designers and human factors specialists to develop and simulate user experiences that are iteratively tested with users. Our software engineers work in an IEC 62304 and 61508 compliant system with our quality and mechanical engineers to ensure that solutions are delivered in a robust and assured format. Our scope of work includes:

Electronics

– System architectures: from small, high performance to large industrial

– Digital, analogue, opto and RF hardware design

– Sensor integration and motion control

– Wireless connectivity solutions

– Microcontrollers, Embedded Software & FPGAs

Software

– Platform & software selection and specification

– Database Design & Code Generation

– Software: Real-Time Processing, C++, Linux, Microsoft CE, Assembler

– Software Validation Management

– Data acquisition, image and video capture and processing

– Post-launch technical support